ENGINEERED TO SUCCEED

EASIER TO USE, FASTER TO INSTALL, AVAILABLE UP TO 120" IN SIZE OR LARGER.

Spirolite® is a specialized HDPE fluid network conveyance system encompassing pipe, fittings, manholes and structures made from spirally wound HDPE pipe in open, closed or solid wall profiles up to 120” diameter, or larger.

Spirolite is the leading technology in large diameter thermoplastic pipes. Cost-efficient, lightweight, durable, weather and corrosion-resistant, these specialty pipes can function under a wide temperature range and are designed for easy assembly. Spirolite is the preferred replacement for the traditional materials used for sewers (concrete), since it is more resistant to pressure, needs less maintenance and has a longer service life.

Key Benefits:

- Long lasting and flexible HDPE system

- Cost effective when compared to traditional piping systems for municipal and industrial waste applications

- Available in diameters between 18” and 120” inside diameter

- Bell and spigot joint design or plain-ended field-welded joint

- Reduces installation time and assures corrosion resistance for long-term durability

Spirolite pipe can

benefit your projects.

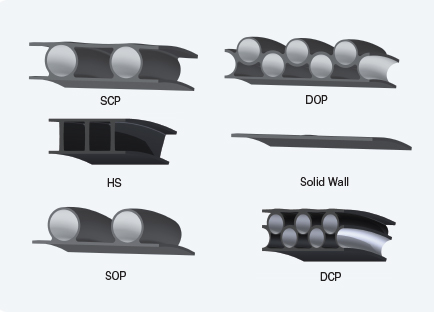

PROFILE WALL CONCEPT

Spirolite®’s unique manufacturing processes is the only HDPE system in the United States that truly offers an engineered cost competitive alternative to traditional piping systems in applications of gravity and low pressure sanitary sewer systems, odor control ductwork, as well as industrial waste applications.

Spirolite® pipe is manufactured to constant internal diameters produced to the following standards: ASTM F894, ISO 21138, DIN 16961, EN 13476 as well as other international standards, pending the application. Sizes up to 120” diameters are standard. Additional sizes through 144” are available upon request. We can also customize. The beauty of the profile wall concept is that any of the parameters, including wall thickness, tube diameter, rib spacing, and more, can be varied to create a custom designed pipe for any specific application.

BELL & SPIGOT

The Spirolite® pipe gasket is designed to meet ASTM F477. This easily assembled joint is perfect for sanitary sewer and most industrial waste applications and is available in 18” through 120” diameter Spirolite® pipe. The gasket will not “fishmouth” or roll out of its groove when homed.

Because of its unique profile shape, the gasket provides double protected, dual sealing: a compression seal against exfiltration and a combination of compression and hydraulic seal against infiltration. The hydraulic seal is energized by external pressure, thus it becomes tighter with increasing infiltration pressure. This unique design is superior to an O-ring seal which provides only a compression seal.

The Spirolite® pipe joint passes standard air or hydrostatic field testing with ease and is designed in accordance with ASTM D3212 Joints for Drain and Sewer Plastic Pipes using Flexible Elastomeric Seals. Infiltration rates not to exceed 50 gallons/inch of diameter/mile/day may be specified for the Spirolite® pipe gasket joint. Recommended assembly procedures for the gasket joint are given in the Spirolite Installation Guide.

THERMAL WELDED ENDS

The Spirolite® pipe thermal welded joint is used primarily for applications where contact with exotic effluents are anticipated or a higher pressure rating than 25 feet of head is required. Using a portable field extruder, a bead of polyethylene is extruded and fused to the juncture of the bell and spigot to form a homogeneous joint which is absolutely leak proof. The weld bead may be placed on the inside or outside of the pipe or both.

Spirolite Bell and Spigot Joint

Spirolite Bell and Spigot Joint

Spirolite Thermal Welded Bell and Spigot Joint

Spirolite Thermal Welded Bell and Spigot Joint

Spirolite HS Thermal Welded Profile Ends

Spirolite HS Thermal Welded Profile Ends

JOINING METHODS

Spirolite® pipe may be joined by two alternative techniques, each employing the ease of bell and spigot assembly. These are rubber gasket and thermal welding that allow the specifier the option of selecting the method which is best suited for the application.

Number of Joints for HS pipes

| project length(Ft.) |

50' length |

20' length |

13' length |

8' length |

4' length |

| 5000 | 100 | 250 | 385 | 625 | 1250 |

| 10000 | 200 | 500 | 769 | 1250 | 2500 |

| 15000 | 300 | 750 | 1154 | 1854 | 3750 |